ARKPEEK Boosts Production Efficiency with New European PEEK

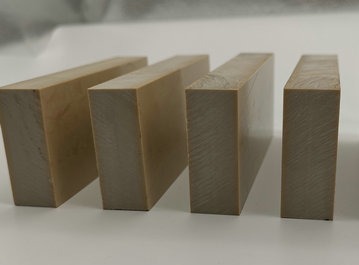

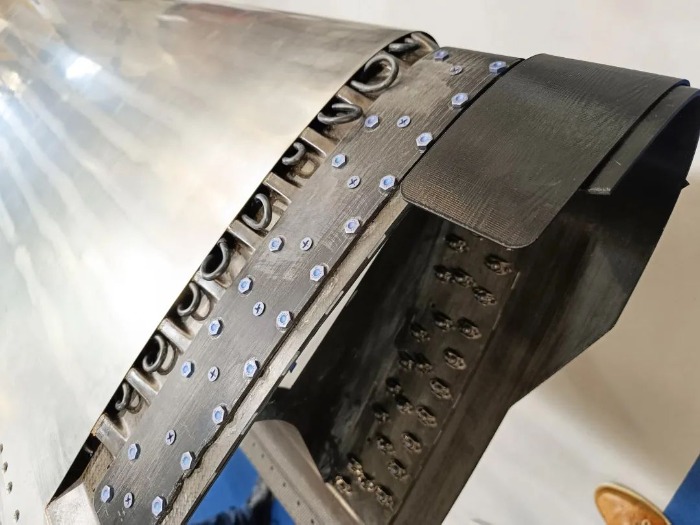

Última realización ・ 28 feb 2024 ・ leer másAfter 12 months of long waiting, on February 28th, ARKPEEK's second European imported PEEK rod continuous extrusion production line entered the factory. The extrusion is more stable, the production efficiency is higher, suitable for large-scale continuous stable production of PEEK rods, helping ARKPEEK improve delivery times and reduce production costs.